Tips to Increase ROI on Skid Steer Tires

There are two key facts to know about skid steer tires: 1) skid steers are tough on tires, and 2) in general, tires are the most expensive consumable item on a skid steer. Considering these two facts, it stands to reason that the more life owners and operators squeeze out of a tire, the greater their return on investment.

The most common causes for the hastened wear of skid steer tires can be divided into two categories: operators and application. Keep reading to learn the subtle (and not-so-subtle) ways in which you could be burning through your tires, and the steps that you can take to increase the life, and ROI, of your skid steer tires.

How Operators Influence Skid Steer Tire Wear

When on the move: Improper operation of a skid steer is the leading cause of preventable tire wear on skid steers. A good rule of thumb for skid steer operators is spinning wheels = spending money, which is especially true when working on hard, abrasive surfaces. Similarly, making numerous tight turns can escalate the amount of wear induced by the counter rotation of tires. If possible make turns before getting on a hard surface and when you have to make turns on rough surfaces try to make wide-radius turns. Training operators and prioritizing the proper operation of a skid steer can go a long way to reducing tire costs.

Know your limitations: Tire manufacturers engineer skid steer tires to operate at certain loads and speeds. Asking a tire to carry a load heavier than its rating places it under undue stress, leading to shorter tire life (best case) or causing catastrophic failure (worst case). Running a skid steer faster than its tires’ speed rating can cause heat to build up quicker than it's able to be dispersed, leading to reduced service life. Find the speed and load rating for our line of Galaxy skid steer tires on our website or on our mobile tire app (available for both iOS and Android) and act accordingly.

Maintaining skid steer tires: Frequently inspecting for signs of wear like chunking, cracks, embedded debris, and tread wear is an excellent way to maximize the life of your skid steer tires. This practice can signal potential problems, allowing you to take action before they become emergencies. If your skid steer is equipped with pneumatic tires, it’s a good idea to check the tire pressure before operating the machine. Over-inflation can cause uneven wear and increase the chances of damage inflicted by impacts, while under-inflation can result in excessive heat build-up, tire separation, and uneven wear.

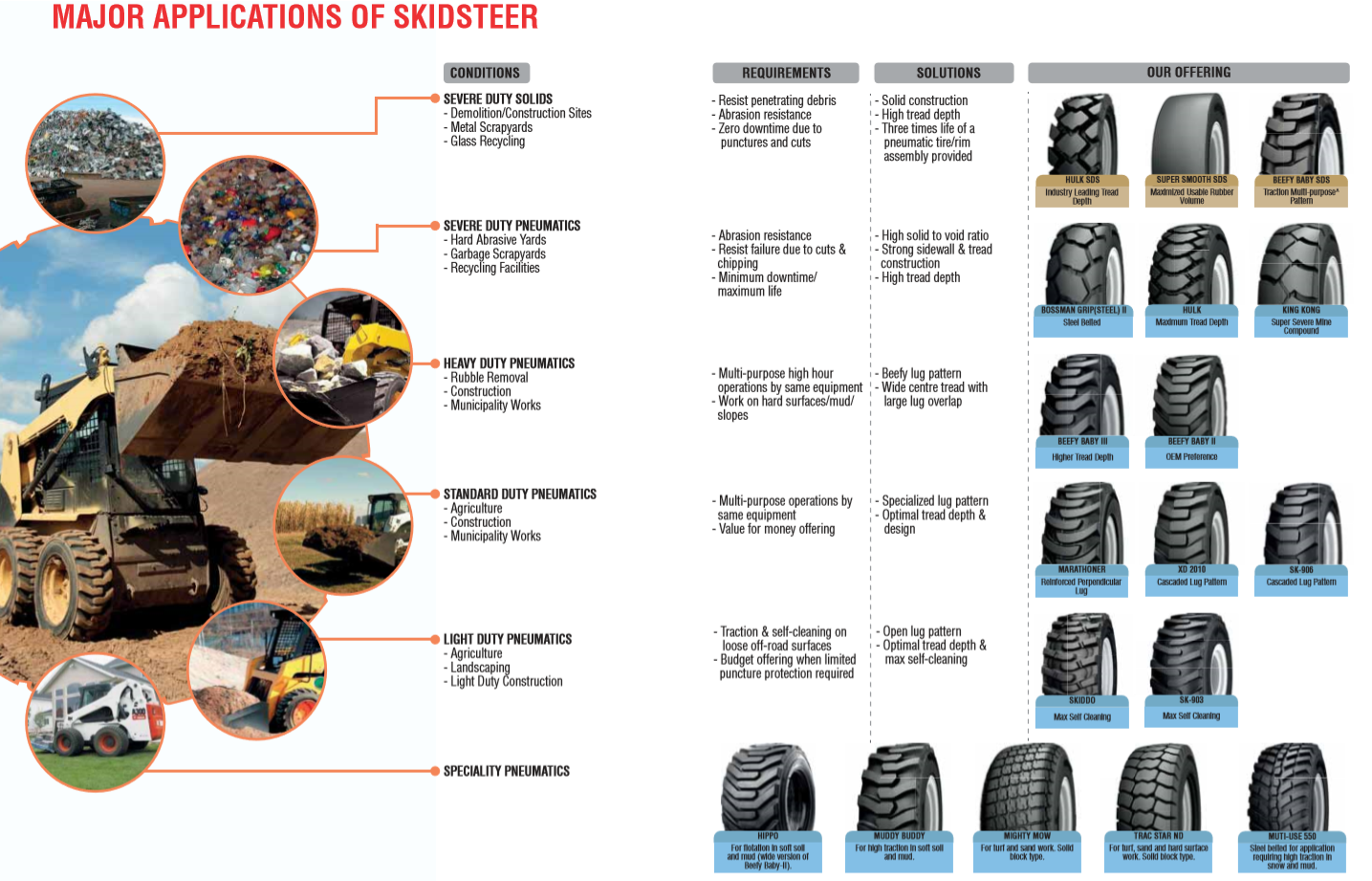

Click on the image above to enlarge

How Application Influences Skid Steer Tire Wear

Application-specific: Skid steer tires are asked to perform a wide variety of jobs in diverse types of terrain. With this in mind, the skid steer tire best suited for a machine working in a scrapyard isn’t the ideal tire choice for a machine performing landscape work. Outfitting a machine with a tire designed for the type of work and conditions it will encounter will not only increase the longevity of your tires but also increase the productivity and efficiency of your skid steer.

Solid vs. pneumatic: Traditionally, skid steers have been equipped with pneumatic tires. Pneumatics provide varying levels of ruggedness—ranging from severe-duty tires like our Galaxy Hulk to light-duty tires such as our Galaxy Skiddo—and are a fantastic choice for most applications. However, solid skid steer tires are increasing in popularity on machines operating in the most challenging conditions. Due to their puncture-proof construction, solid tires are the go-to choice for machines working in demolition, metal scrapyards, and glass recycling. More costly up front than pneumatics, solid tires can prove a better investment than a pneumatic on a machine operating in harsh conditions and provide a lower total cost of ownership thanks to their ability to stand up to tough terrain, reduce downtime, and keep operations productive.

Tread time: The type of tread on a skid steer tire will also affect its longevity, efficiency, and, ultimately, ROI. Tires with deep treads, such as our Galaxy Muddy Buddy, are ideal for working on soft surfaces like slop and sand. Alternately, tires like our Galaxy Super Smooth SDS are ideal for operating on hard surfaces. The massive tread blocks of our Galaxy Hulk SDS means there is more rubber to wear, which results in a longer-lasting tire. This is one reason we’re so excited about the 66% higher non-skid depth (NSD) than standard solid tires and the 68% lug-to-depth ratio found on our Galaxy Hulk SDS.

The Takeaway

Ensuring proper operation of your skid steer along with equipping it with the right set of tires can result in increased productivity and efficiency while decreasing downtime and expense. While we can’t help you with overly aggressive operators, we can help you with tire choice—our Galaxy line of skid steer tires has an application-specific tire for all types of industries. Contact your local dealer or rep today to learn more.